LIGHTBOND

ULTRA LIGHT SANDWICH SOUND FINISHING PANELS

Lightbond is our solution to combine weight reduction and quality cladding. Usage of Lightbond meets the need to create a higher quality level in an easy applicable, and an environmentally friendly method.

Weight reduction: This precoated lightweight cladding material reduces the added weight of cladding systems up to 10 kg per Sqm compared.

Smooth Apllication: The high stiffness of the materials offers the possibility to use rivets without denting the sheet. This give you a nice and high-quality surface.

QUICK and EASY: Applying Bondal Aluminium, as a precoated cladding part of the ship, reduces the amount of painting labor and drying time substantially, which are required by using regular steel or aluminium surfaces. Application can be done with rivets or just glue the sheets against the framework.

Coating: Bondal Aluminium is pre coated with a polyester paint. Standard color are RAL 9003 and RAL 9010. Both are coated in high gloss. Correction can be made with polyester paint or, after using a primer, a polyurethan paint. Maximum temperature for the coating is 70 degrees Celsius.

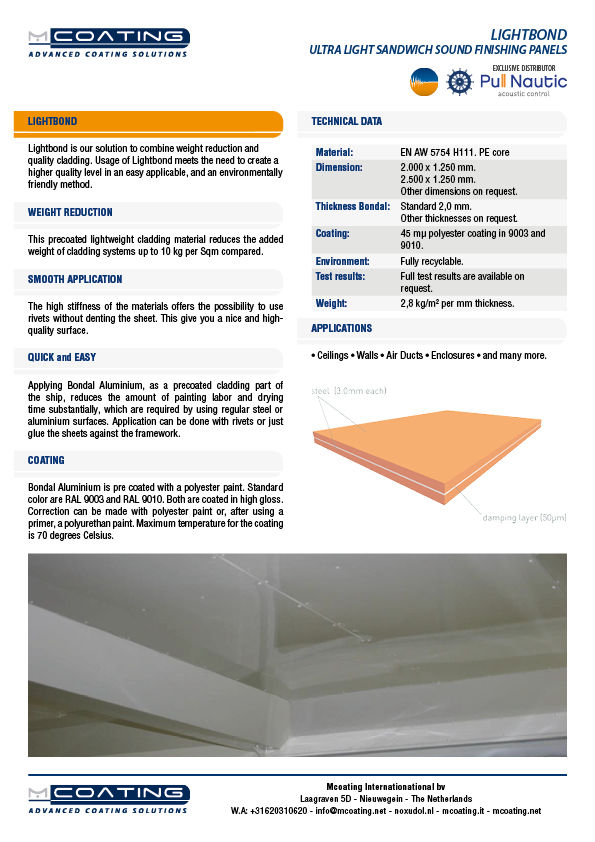

Dimensions:

2.000 x 1.250 mm.

2.500 x 1.250 mm.

Other dimensions on request.

Thickness:

Bondal Standard 2,0 mm.

Other thicknesses on request.

Coating: 45 mμ polyester coating in 9003 and 9010.

Weight:

2,8 kg/m² per mm thickness.

Applications:

• Ceilings • Walls • Air Ducts • Enclosures • and many more.